All Categories

Featured

Table of Contents

- – Commercial Kitchen Exhaust Fan Installation Alt...

- – Instant Air Solutions

- – Hvac Service Technician Altadena, CA

- – Fix Air Conditioner Compressor Altadena, CA

- – Hvac Emergency Repair Altadena, CA

- – Air Conditioning Repair Contractor Altadena, CA

- – Commercial Ac Repair Altadena, CA

- – Central Air Conditioning Altadena, CA

- – Heating And Cooling Repair Altadena, CA

- – Commercial Rooftop Unit Repair Altadena, CA

- – Ac Repair Near Me Altadena, CA

- – Commercial Air Conditioning Installation Alt...

- – Instant Air Solutions

Commercial Kitchen Exhaust Fan Installation Altadena, CA

Much of our competitors got their begin benefiting us. We educated them on just how to supply solution on all hoods, followers, heated makeup air systems and air cleansers. We additionally set up, preserve and repair commercial kitchen area pollution control devices and electro-static precipitators such as the SMOG HOG. See this VIDEO ON THE RIGHT? There's a reason it has over 21,000 sights.

Several of the crucial services that such a company should provide include: This is an essential solution that removes grease and other contaminants from the exhaust hood, ductwork, and follower. This assists to stop fire hazards and keep excellent air quality. 24/7 Kitchen Exhaust Service Altadena. The business ought to inspect, tidy, and lube the cooking area exhaust follower to make certain that it is operating successfully and silently

The firm needs to offer routine assessments and maintenance solutions for the kitchen's fire reductions system to make certain that it is functioning effectively in the event of a fire. The business should perform air equilibrium testing to guarantee that the ventilation system is giving sufficient air movement and correct air exchange. The business must have a complete understanding of all relevant codes and policies controling kitchen air flow systems and guarantee that the customer's system remains in compliance.

We supply quality solution & affordable pricing. Utilizing our state-of-the-art software program, we'll function with your designers and according to your strategies and Engineer Designs. Or we can supply these for you for a complete turnkey fire protection services option for your restaurant cooking area. This consists of all mechanical, electric, plumbing, and hoods.

Hvac Service Technician Altadena, CA

Published November 2, 2021 Your restaurant kitchen depends upon an operating hood to avoid fires, so you and you team requirement to take care of commercial hood repair work rapidly when issues happen. At Peak Hood Cleansing, we have actually been cleaning, keeping, and repairing industrial restaurant cooking area hoods and exhaust systems considering that 1978. We serve cities and communities along the Northwest Pacific coast of Oregon and Washington.

Dining establishment Ventilation systems are extremely vital for the whole performance of a business food preparation location. Without having a correct exhaust system, a lot of problems can arise, and the results would be regrettable. Regardless of their fundamental demands and requirements, some systems are installed in a very bad means, and this after that becomes a danger to constructing locals.

Several are installed without the ideal access doors, positioned too close to heat sources or combustible products, or have more than one connection from various warm resources. Any of these poor setups can lead to serious fire threats. To secure your structure, your personnel, and your clients, it's extremely essential to see to it your restaurant ventilation system is without these issues.

Most of the time, your commercial exhaust fans may not be at the top of your listing. It's vital that you pay interest to the exhaust systems and industrial fans in your structure.

Fix Air Conditioner Compressor Altadena, CA

In situation you want to learn even more concerning the listing of possible problems, we are offering you with the correct listing. This article will talk about some generally faced problems entailing exhaust hoods and other facets of your restaurant ventilation systems. All gain access to panels need to be effectively sized to enable for duct cleansing.

If these policies aren't complied with, it can protect against important cleansing and upkeep of your exhaust system. In the worst-case circumstance, this can come to be a significant fire danger and a threat for any person nearby. An absence of cleansing, inspection, and upkeep can lead to a buildup of grease and oil, which raises the danger of cooking area fires.

Because exhaust systems act as air filters, failing to cleanse them appropriately can transform your cooking area right into an unsafe location. Experts recommend cleansing your system at the very least every 90 days.

To examine for dampness infiltration, shut off the exhaust system and carefully eliminate the follower cover. This easy check can help avoid major problems prior to they begin. Another significant problem that can influence your restaurant ventilation system is a power failure. This might take place due to system failure or a faulty power supply.

Hvac Emergency Repair Altadena, CA

Numerous industrial cooking area fires are caused by unintentional flare-ups from stovetops. When an oil elimination gadget is mounted too near to a heat source, these flare-ups can become explosive fires inside the hood and ductwork. To stop this, there need to go to least 18 inches of room in between any kind of grease elimination tool and the food preparation surface.

These cooking techniques lug a higher risk of ignition and have different, committed ventilation systems. Usually, kitchen area exhaust hoods and filters lie near the lessee's area, while the ductwork and exhaust fan are mounted in the main areas of the structure. Because of this arrangement, it's necessary to remain organized and connect plainly when organizing maintenance programs.

To shield your kitchenand everyone around youit's essential to understand the possible threats within your exhaust system. You must also take some time to find out about all the elements and mechanical systems included. Most significantly, make it a routine to regularly evaluate your system for oil build-up, as this is one of the biggest fire threats in industrial kitchens.

Air Conditioning Repair Contractor Altadena, CA

: Evaluate and oil follower electric motors and bearings as required to make certain smooth operation and stop overheating. Replace any type of damaged or defective parts promptly.: Regularly evaluate ductwork for any kind of leaks, clogs, or damage. Clean ducts to eliminate built up oil, dust, and debris.: Monitor the performance of the exhaust system consistently to ensure it is effectively eliminating cooking smells, smoke, and grease from the kitchen area setting.

Inspect if the power supply is attached, the follower motor is useful, and the filters or air ducts are not blocked. This might be due to stopped up filters, a failing fan electric motor, poor hood style, not enough CFM (air flow), or obstructed ductwork.

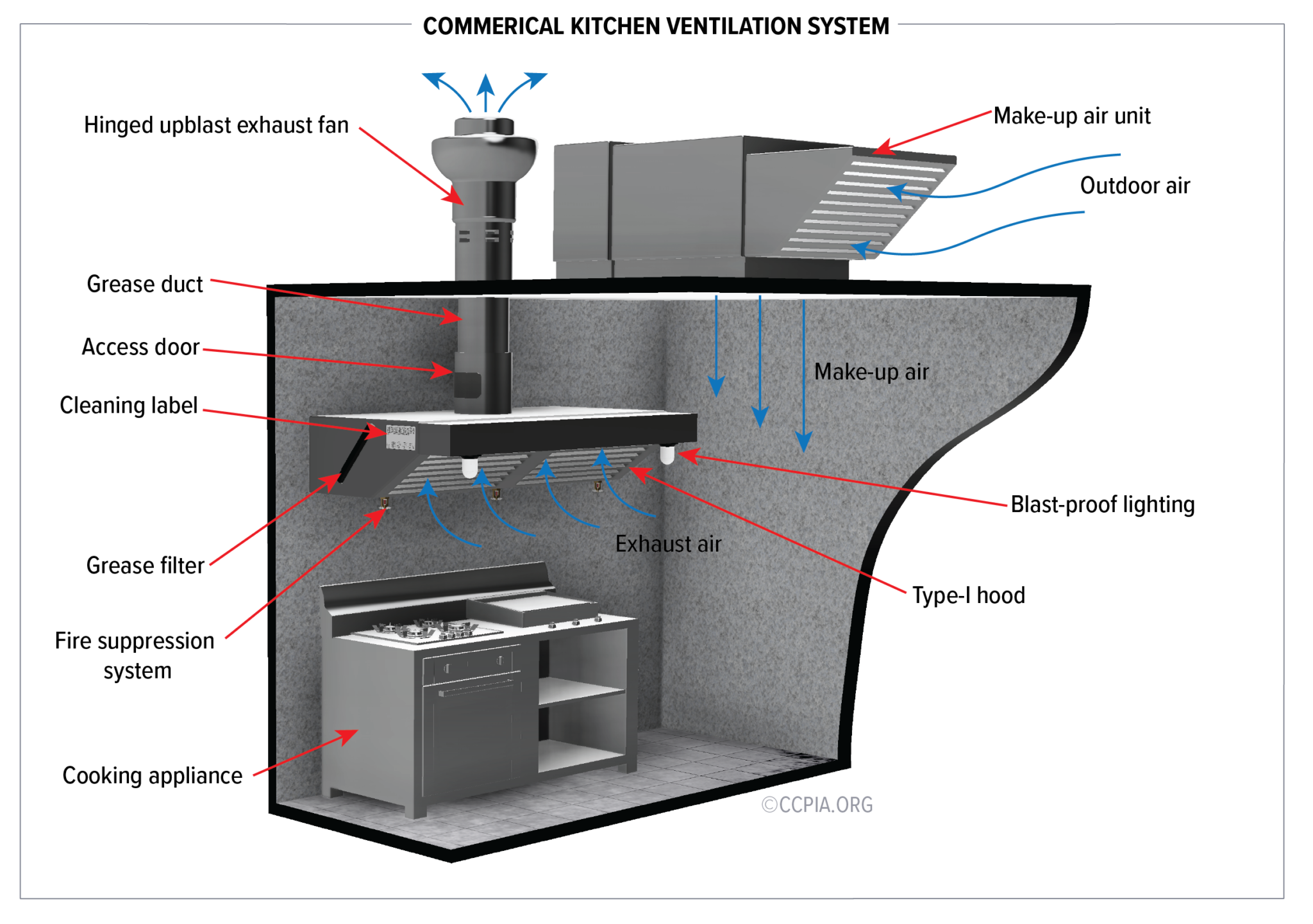

Click on a hotspot to view items that connect to the image on the diagram. The picture over shows a typical industrial kitchen application making use of a roof covering mount upblast exhaust follower OR wall-mount upblast exhaust follower combined with a supply fan (24/7 Kitchen Exhaust Service Altadena). Note that not both exhaust followers are required for hood exhaust

Commercial Ac Repair Altadena, CA

A good system maintains your kitchen area secure and in conformity with guidelines. We're talking about the nuts and bolts of hoodseach kind, its task, and why they're non-negotiable. From grease-catching baffle filters to sleek canopy hoods, each contributes in security. Safety conformity is big, certainly. It's not just a matter of mounting and forgetting.

Air flow isn't a set-and-forget deal. Expert oversight is crucial. Evaluations capture issues before they get large. Safety and security and performance work together. We dive deep with these basics. You receive a cooking area that is safe and compliant. Let's simplify and understand everything. To make sure a risk-free food preparation setting, a trusted business cooking area air flow system is crucial for managing cooking vapors and maintaining good air high quality.

By properly eliminating cooking vapors and air-borne toxins, cooking area hoods add to a trusted and certified cooking atmosphere, eventually sustaining the total safety and security and effectiveness of food preparation operations. The same is real when it comes to cooking area ventilation systems it's not a one-size-fits-all scenario. There are 2 main kinds of business kitchen area exhaust hoods: Type I and Kind II.

These systems normally include followers, ducts, and filters. They interact to remove smoke, warm, and smells. Think about the fan as the heart, pumping all that poor air out. The air ducts are the capillaries, lugging the air out. Filters, on the various other hand, catch oil and bits, keeping that air movement clean and risk-free.

Central Air Conditioning Altadena, CA

You want components that'll last and can hold up against the warm and oil of an active kitchen. In addition, the elements need to work with each other well. If the follower is too weak, the system can have a hard time to obtain going. Additionally, slim air ducts can negatively affect performance, making it challenging for the dryer to properly remove air.

You just require great to catch it before it creates issues. Routine cleansing is the name of the video game below; filthy filters trigger grease fires that threaten and expensive. As a best method, tidy filters on a set routine relying on exactly how much you do your food preparation. Nobody desires a fire to burst out easily.

They maintain oil out of the pipelines to avoid blockages. Cleaning these catches assists your kitchen area stay secure and hygienic. If you comply with these steps, you will stay clear of a great deal of migraines in the future. are a necessity when it pertains to a business kitchen area air flow system. They give important access to cleanse the ducts, which is vital for the reliable operation of the exhaust system.

The NFPA 96 Requirement details important security demands, covering every little thing from the design of kitchen air flow systems to the setup of commercial cooking area exhaust hoods. This detailed strategy guarantees that cooking areas preserve a dependable kitchen area atmosphere while properly handling cooking vapors and grease. Understanding the technological requirements for different hood kinds is crucial for compliance.

Heating And Cooling Repair Altadena, CA

This is where kitchen area drivers typically flounder: they fail to remember to compute the required air flow. Accurate measurements for the commercial kitchen exhaust hood measurements are crucial to attaining optimum performance. Obtaining it incorrect can lead to a great smoky mess and ineffective oil monitoring techniques. Correct setup of the exhaust hood systems makes certain that air moves successfully, protecting against the build-up of airborne toxins.

This proper labeling assists preserve the necessary ventilation and guarantees the security of cooking area operators. Securing these hoods appropriately is imperative to avoid accidents in a busy kitchen area setting. Guaranteeing that the business kitchen area air flow system is effectively installed and maintained can dramatically lower possible risks, developing a secure food preparation atmosphere for all.

These hoods are particularly designed for warmth and vapor, as seen over dishwashers. They offer adaptability, occasionally even eliminating the need for ductwork, making them a cost-efficient option for kitchen area drivers. Sealing the joints and seams of these hoods is crucial for correct kitchen area ventilation. This practice guarantees whatever continues to be limited and effective, properly managing dampness and heavy steam while offering a reputable kitchen area setting.

These advancements are defining the future of cleaner, smarter kitchens and boosting cooking area efficiency. With functions like automatic fire defense and effective oil filters, these industrial kitchen hood systems not only enhance safety yet likewise sustain the cooking procedures. As we embrace these innovations, we lead the means for a much better cooking experience and a much safer work environment.

Commercial Rooftop Unit Repair Altadena, CA

Dust, allergens, and other contaminants can build up in the air ducts over time, resulting in possible health and wellness problems and decreased system performance. Below's a quick review of what that entails: First, it's important to check the entire system for any kind of indicators of dirt or clogs. This consists of examining the ducts, filters, and vents.

: Demand cleaning at the very least twice a week. You wish to get certified pros since they recognize your system in and out. Their knowledge is important in keeping the integrity of your heating and cooling systems. Furthermore, accredited experts help prevent terrifying concerns like oil fires. They are educated to recognize and reduce threats that can position a threat to your home.

This is where cooking area operators frequently trip up: they fail to remember to compute the needed ventilation. Exact measurements for the industrial kitchen exhaust hood dimensions are key to attaining ideal efficiency. Obtaining it incorrect can result in a great smoky mess and inefficient grease monitoring practices. Appropriate configuration of the exhaust hood systems makes sure that air flows properly, avoiding the build-up of airborne toxins.

Ac Repair Near Me Altadena, CA

This appropriate labeling assists maintain the required air flow and ensures the safety and security of cooking area operators. Protecting these hoods correctly is necessary to stop accidents in an active cooking area environment. Ensuring that the commercial cooking area air flow system is correctly set up and preserved can substantially reduce prospective dangers, creating a secure food preparation environment for all.

They offer flexibility, in some cases also getting rid of the need for ductwork, making them an economical option for kitchen drivers. Sealing the joints and joints of these hoods is vital for proper cooking area air flow.

These developments are specifying the future of cleaner, smarter cooking areas and enhancing kitchen performance. With functions like automatic fire protection and effective oil filters, these industrial kitchen hood systems not only boost security but likewise sustain the cooking operations. As we welcome these advancements, we lead the means for a far better cooking experience and a safer work environment.

Dust, irritants, and various other contaminants can collect in the air ducts with time, bring about potential health issues and lowered system efficiency. Below's a quick rundown of what that involves: First, it's vital to evaluate the entire system for any type of indicators of dirt or obstructions. This includes checking the ducts, filters, and vents.

Commercial Air Conditioning Installation Altadena, CA

Instant Air Solutions

Address: 412 W Dryden St Apt 6 Glendale, CA 91202Phone: (747) 307-6363

Email: [email protected]

Instant Air Solutions

: Need cleansing at the very least two times a week. You wish to get licensed pros because they know your system in and out. Their know-how is essential in preserving the integrity of your home heating and cooling down systems. In addition, licensed experts help protect against terrifying issues like grease fires. They are trained to identify and alleviate risks that can posture a threat to your home.

Commercial Kitchen Hood Maintenance Altadena, CAAc Repair Company Altadena, CA

Air Conditioner Companies Altadena, CA

Hvac Emergency Repair Altadena, CA

Commercial Kitchen Hood Maintenance Altadena, CA

Close By Seo Companies Near Me Altadena, CA

Best Seo Companies Near Me Altadena, CA

24/7 Kitchen Exhaust Service Altadena, CA

Instant Air Solutions

Table of Contents

- – Commercial Kitchen Exhaust Fan Installation Alt...

- – Instant Air Solutions

- – Hvac Service Technician Altadena, CA

- – Fix Air Conditioner Compressor Altadena, CA

- – Hvac Emergency Repair Altadena, CA

- – Air Conditioning Repair Contractor Altadena, CA

- – Commercial Ac Repair Altadena, CA

- – Central Air Conditioning Altadena, CA

- – Heating And Cooling Repair Altadena, CA

- – Commercial Rooftop Unit Repair Altadena, CA

- – Ac Repair Near Me Altadena, CA

- – Commercial Air Conditioning Installation Alt...

- – Instant Air Solutions

Latest Posts

Norco Senior Photographer

Diamond Bar Senior Pictures

Emeryville Contractor For Concrete Patio

More

Latest Posts

Norco Senior Photographer

Diamond Bar Senior Pictures

Emeryville Contractor For Concrete Patio