All Categories

Featured

Table of Contents

- – Evaporative Cooler Pump Repair Sunland, CA

- – Instant Air Solutions

- – Swamp Cooler Repair Near Me Sunland, CA

- – Evaporative Cooler Repair Sunland, CA

- – Repair Swamp Cooler Sunland, CA

- – Commercial Swamp Cooler Repair Sunland, CA

- – Commercial Swamp Cooler Repair Sunland, CA

- – Evaporative Cooler Installation Sunland, CA

- – Swamp Cooler Repair Service Sunland, CA

- – Swamp Cooler Repair Service Sunland, CA

- – Evaporative Cooler Pump Repair Sunland, CA

- – Evaporative Cooling Repair Near Me Sunland, CA

- – Evaporative Cooler Rust Repair Sunland, CA

- – Evaporative Cooler Pump Repair Sunland, CA

- – Swamp Cooler Motor Repair Sunland, CA

- – Instant Air Solutions

Evaporative Cooler Pump Repair Sunland, CA

If you have any type of idea what components comprise an overload cooler, identifying the origin of the breakdown ought to not be too hard. Adhering to are the swamp cooler parts most prone to encounter problems: Two primary types of electric issues can affect overload coolers. The first kind is defective wiring.

When an irregular quantity of electricity flows right into your cooler due to malfunctioning wiring, the system might wind up with a blown fuse. Swamp colders likewise break down when they are not receiving sufficient electrical energy. For such a thing to occur, you might have plugged the cooler into a harmed outlet or one that is not created the cooler.

Swamp Cooler Repair Near Me Sunland, CA

If your colder is not blowing air out hard enough, one problem might be the lack of exhaust. To be able to do its task, an evaporative cooler needs adequate air flow and blood circulation. The ducts in the area where the cooler is mounted should have the ability to provide sufficient exhaust.

In situation there is no air burning out of the colder in any way, there could be a problem with the pump. You can likewise make added sure by inspecting the integrates and brokers to see if they are blown or stumbled. In such an instance, thermostats can also be considered.

Evaporative Cooler Repair Sunland, CA

The humming noise suggests that the motor is getting power however isn't transforming. This trouble might come from a damaged capacitor, which assists the electric motor start by supplying a first shock of electrical energy. An additional opportunity is that the electric motor's bearings are confiscated or there's particles blocking the fan blades. Examining the capacitor for bulging or leak and making certain the fan blades can rotate freely are crucial actions.

When your colder is not blowing out chilly air, you can expect three primary issues. Overload coolers need a resource of fresh air.

When your room is humid, the air currently has as well much water vapor, and that implies the water in the colder can not evaporate. If the pads are not saturated sufficient, the colder will certainly not be able to generate cool air.

Below are a few of the most typical problems that can be troubleshot, either by you on your own or a specialist. Overload coolers have fewer digital parts contrasted to air conditioning system. Because of that, you can expect one of the most typical reason for the electric motor spoiling to be a blown fuse.

Repair Swamp Cooler Sunland, CA

You can attempt resetting the breaker first, and if you keep discovering yourself needing to reset it, you might have to replace the damaged electrical wiring. A colder's belt attaches the motor and the follower. If that breaks off the follower stops functioning. The electric motor may be running, but the system is not generating air.

A broken belt will be a great deal more difficult to deal with given that you will have to discover a compatible replacement belt and slide that right into placement. The most obvious out of these issues has to be a motor failure. If the electric motor is warm after you activate the follower for a couple of minutes and turn it off, a substitute may be required.

Commercial Swamp Cooler Repair Sunland, CA

Kitchen area Solutions is just a phone call away. Call us at (332) 310-2010 If you discover that your pump colder is dead, you can try validating that by making certain there is water present at the base of your cooler. Examine whether the pump is obtaining power as some pumps are made to connect guiding right into a basic outlet, while others are wired inside a box existing in the colder.

Extremely commonly, debris and range tend to build up, obstructing water flow to the pump. You will certainly locate the pump at the bottom of the overload cooler.

You should see to it that the motor is obtaining enough electrical power to be able to launch. If any kind of device does not get enough voltage for some time, it might heat up. You can examine the power plug making use of a voltmeter to discover if there are any type of problems with the voltage intake.

Commercial Swamp Cooler Repair Sunland, CA

If the cords show up corroded, your cooler may have defective cabling. You might have to fix the breaker as well as the cord linked to it.

A damaged electric motor fan may additionally maintain the motor from beginning. Evaluate the fan by starting it for some time. Consider disabling the connector plug and taking off the panel. Inspect to see if the motor is warm. If the engine emits heat, the equipment might have to be changed.

Take into consideration getting in touch with a service technician at Kitchen area Solutions to obtain your overload cooler motor concern repaired. If the evaporative cooler stops working to burn out awesome air, the water supply might be the cause. Colders can not generate trendy air if their pads are not completely soaked. Touch the pads to check if they are still wet.

Evaporative Cooler Installation Sunland, CA

As for the overload cooler pump not functioning, you might need to change it. Examine the valves to see if they are malfunctioning, or if televisions are clogged. Such issues stop water from obtaining to the pads. Evaporative colders can damage down due to a number of problems. Common troubles consist of clogged or filthy cooling pads, which reduce efficiency; a malfunctioning water pump, protecting against appropriate water circulation; and a defective motor or fan, leading to inadequate air flow.

Regular maintenance, consisting of cleaning pads and inspecting water degrees, can aid prevent these concerns and extend the life of the colder. Clean the cooling pads, water storage tank, and filterings system on a regular basis to avoid obstructions and mineral build-up. Examine the water pump, motor, and follower for signs of wear or breakdown and address concerns immediately.

Prior to the air conditioning season starts, execute a comprehensive evaluation and upkeep to guarantee all parts are operating correctly. For DIY fixes for exactly how to repair a swamp cooler and evaporative cooler troubleshooting, our guide can aid recognize whether you require a brand-new pump for evaporative colder, evap cooler pumps, and even a water pump overload cooler substitute.

In verdict, addressing usual swamp cooler issues calls for a comprehensive understanding of the unit's parts and their features. Routine maintenance, such as cleaning the filters, checking the water system, and evaluating the motor and pump, can protect against numerous issues. Typical troubles like poor cooling, unusual sounds, or water circulation failings commonly have straightforward solutions, yet relentless problems could indicate even more significant underlying troubles.

Swamp Cooler Repair Service Sunland, CA

If problems linger, looking for professional support can aid fix intricate issues and expand the life expectancy of your cooler. When swamp coolers scent similar to this, it indicates that their water frying pan has not been replaced in a while. The water grows stagnant when there is no room for evaporation, causing new bacteria to expand.

Remove the pads from the colder and use a vacuum cleaner to get rid of loosened debris. Calcium down payments have a tendency to build up over time on swamp pads.

Swamp Cooler Repair Service Sunland, CA

Prior to winterizing the evaporator colder, you need to drain the system, get rid of the pads, and tidy the container. If your overload cooler is not blowing hard enough or rarely blowing air at all the swamp cooler pump may not be working effectively.

A swamp cooler that doesn't work at all could have an unsuccessful electric motor. If the exterior of your swamp cooler is corroded, the indoor most likely is as well.

This can indicate that the cooling effect from an evaporative colder will certainly be lowered. The most typical factor the evaporative cooler may not be providing an excellent air circulation is as a result of the circuit breaker and fuse of the evaporative colder, which are installed by the producer to avoid damages to the device.

To reset an overload cooler, start by transforming off the power to make sure safety and security. Separate the cooler from its electrical source or change off the circuit breaker.

Evaporative Cooler Pump Repair Sunland, CA

As soon as whatever looks good, turn the power back on by reconnecting the cooler or switching the circuit breaker back to the "on" placement. Finally, restart the swamp cooler and change the settings as required. If the cooler falls short to reset or proceeds to malfunction, refer to the individual handbook or look for professional support for more troubleshooting and repair.

Beginning by examining the water supply to make certain that the water shutoff is open and there's appropriate circulation to the colder. Evaluate the water circulation system, consisting of the water pump, for any kind of obstructions or breakdowns.

If these steps don't settle the problem, there could be an issue with the water lines or the cooler's inner components, needing expert solution. If your overload cooler isn't switching on, examine for issues like a tripped circuit breaker, separated power supply, damaged thermostat, or a defective capacitor. Make sure the water system is working and the unit is properly linked.

Guarantee correct upkeep and check for blockages to avoid getting too hot and ensure efficient procedure. A swamp cooler making a loud bustling noise could be due to a malfunctioning electric motor, loose or damaged fan blades, or particles caught in the device. Look for obstructions, make sure all elements are safe, and think about professional repair if needed.

Evaporative Cooling Repair Near Me Sunland, CA

To examine a swamp cooler motor, switch off the power and check the motor for noticeable damage. Utilize a multimeter to inspect for continuity in the windings and verify voltage at the motor terminals. Guarantee the capacitor and circuitry are functioning properly. You could think your swamp cooler is stopping working if it produces weak or no air movement, has an unusual sound, or if the air isn't cooling properly.

Often, the motor can not spin since the fan blade, blower wheel, or belt is obstructed by debris or rust. Loosened or busted electrical wiring, or a poor button or thermostat, can also quit power from getting to the electric motor. Always shut off the power initially, then examine for blockages, examination the capacitor, examine circuitry, and see if the motor turns freely by hand.

Make certain the water supply shutoff to the cooler is open so water can flow right into the pads. Switch on the pump button to let the water saturate the pads for a few minutesthis helps the cooler job a lot more efficiently. After the pads are wet, turn on the fan or blower change to start blowing amazing air into your space.

Evaporative Cooler Rust Repair Sunland, CA

Constantly inspect that there's adequate water in the tank and that the colder is tidy before usage for best performance. A clicking sound generally shows loose parts such as the follower blade, motor places, or drive belt. It can also be triggered by debris inside the cooler striking relocating components.

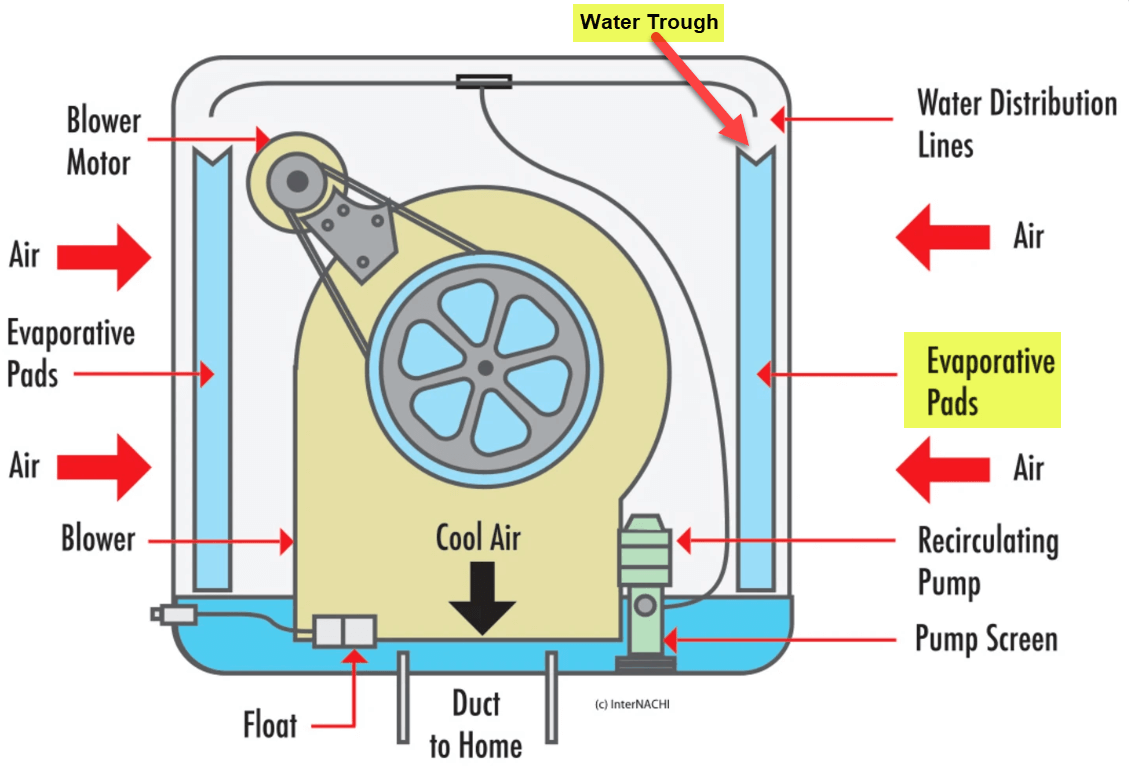

In low-humidity areas, evaporating water right into the air supplies a natural and energy-efficient ways of cooling. Evaporative colders, likewise referred to as overload coolers, utilize this principle. By passing outside air over water-saturated pads, the water in the pads vaporizes, decreasing the air temperature level by 15 to 40F before it is guided right into the home.

A swamp cooler, likewise called an evaporative cooler, is a tool that cools down air with the dissipation of water. It functions best in completely dry environments considering that it adds humidity to the air while reducing the temperature level. The basic components include a fan, a water storage tank, and pads that soak up and vaporize water.

Evaporative Cooler Pump Repair Sunland, CA

We provide same-day appointments, totally free quotes, and honest suggestions to aid you make the finest decision for your home.

Swamp colders are a fantastic option for homes in some locations and especially for older homes, however not all homes are ideal for cooling down by a swamp cooler. Modern ac system are often the preferred selection for home owners getting older and more recent homes. With that claimed, there are numerous reasons that property owners must take into consideration removing their overload cooler and switching over to a more modern approach of cooling their home.

Overload coolers can be gotten rid of as a result of problems that may emerge after they have obtained old or since the home owner wishes to improve their cooling system. After a while swamp colders can run into issues such as deterioration and water damage, not cooling down the home sufficiently, and water leakages. Every one of these issues can trigger troubles with the roof and the foundation of the home if the damage prolongs past the roofing system.

One more failure of overload colders is the amount of upkeep it requires to keep them running smoothly and for a long period of time. Modern a/c call for much less maintenance and repair services and usually last longer than common swamp coolers. Overload coolers are not constantly trustworthy and it can be extra aggravating when it is the middle of the summertime and the heat is soaking right into your home.

Swamp Cooler Motor Repair Sunland, CA

There is not a basic response to this inquiry since all of it depends upon your preferences and what your demands are for your home and building. It additionally relies on why you are intending to remove your overload cooler since it no much longer functions well or due to the fact that you intend to upgrade your cooling system to something a lot more ideal for your home.

Instant Air Solutions

Address: 412 W Dryden St Apt 6 Glendale, CA 91202Phone: (747) 307-6363

Email: [email protected]

Instant Air Solutions

There are several things that can be done by the house owner to do away with these residues and cover the undesirable area left. This hole can additionally allow leaks and sunshine to reveal with into the space of the attic room and upper level rooms. The alternatives for a hide can include: roof covering patches, putting in a sunroof, and mounting a skylight.

Swamp Cooler Pad Replacement Sunland, CAEvaporative Cooler Repair Near Me Sunland, CA

Swamp Cooler Repair Near Me Sunland, CA

Evaporative Cooler Repair Near Me Sunland, CA

Swamp Cooler Replacement Sunland, CA

Near Me Top Seo Company Sunland, CA

Close By Seo Agency Sunland, CA

Instant Air Solutions

Table of Contents

- – Evaporative Cooler Pump Repair Sunland, CA

- – Instant Air Solutions

- – Swamp Cooler Repair Near Me Sunland, CA

- – Evaporative Cooler Repair Sunland, CA

- – Repair Swamp Cooler Sunland, CA

- – Commercial Swamp Cooler Repair Sunland, CA

- – Commercial Swamp Cooler Repair Sunland, CA

- – Evaporative Cooler Installation Sunland, CA

- – Swamp Cooler Repair Service Sunland, CA

- – Swamp Cooler Repair Service Sunland, CA

- – Evaporative Cooler Pump Repair Sunland, CA

- – Evaporative Cooling Repair Near Me Sunland, CA

- – Evaporative Cooler Rust Repair Sunland, CA

- – Evaporative Cooler Pump Repair Sunland, CA

- – Swamp Cooler Motor Repair Sunland, CA

- – Instant Air Solutions

Latest Posts

Kitchen Plumbing University City San Diego

Photographer Family Portraits Mission Viejo

Photographers For Senior Pictures Near Me Corona

More

Latest Posts

Kitchen Plumbing University City San Diego

Photographer Family Portraits Mission Viejo

Photographers For Senior Pictures Near Me Corona